A career in plastic fabrication and welding is as lucrative as any welding jobs. However, fabricating and welding plastic work-pieces together is not as easy as you may think. If you’re thinking of specializing in plastic fabrication and welding, below is an introduction about fabricating plastics, techniques used in welding plastics and safety procedures involved in this line of work.

Other techniques of plastic fabrication and welding include freehand welding (a much slower process but used in many applications), speed-tip welding (a quicker welding technique used in tight corners), extrusion welding (for big pieces), contact welding (two pieces are joined by pinching their heated tips), andhot plate welding (for larger pieces or complex welding technique). High frequency welding, injection welding, ultrasonic welding, friction welding, spin welding, laser welding and solvent welding are also used.

Back to Top

Plastic Fabrication Materials

Different types of plastics exist, each with its own chemical and physical properties. To determine the type of welding to use when joining parts, you should be able to identify the type of plastic first. To do this, you can simply read the labels, or conduct burn tests. The following are some of the common plastics used for manufacturing products:- Polyethylene Terephthalate (PETE) – Since PETE is chemically inert and easily welded, it is used in water tanks and other similar products.

- Polyvinyl Chloride (PVC) – PVC, which is often used in plumbing materials, has varying flexibility and toughness based on plasticizer amount.

- Polypropylene (PP) – This is the most commercial type of plastic used in various industries to make products like lab equipment, and automotive parts (such as those used on radiators), among others. This plastic is very tough that it would not crack even when repeatedly bent.

- High-Density Polyethylene (HDPE) –HDPE is used in ballistic plates, bottles and caps, containers, folding chairs and tables, hula hoops, plastic bags, water pipes and plastic lumber, among other applications.

- Low-Density Polyethylene (LPDE) – When compared to HDPE, LDPE is a much flexible type of plastic. It is used in containers, tubing, laboratory equipment, playground slides and various computer parts.

- Polystyrene (PS) –Although this hard plastic has limited flexibility, it is one of the most used plastics in the world. It is used in packing materials, DVD/CD cases, disposable spoons and forks, hard plastic containers, housing of smoke detectors, and many more.

- Combinations – Plastic fabrication and welding is not limited to just one type of plastic at a time. Sometimes, two or more plastics are combined to create a specific product.

Plastic Fabrication and Welding Techniques

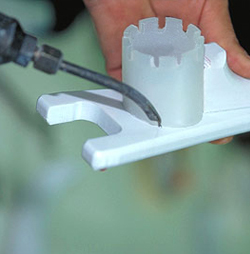

Plastic fabrication and welding involves various techniques, which often use hazardous equipment like gas. For instance, hot gas/ hot air welding involvesa heating gun called “hot air welder” softens the plastic parts, which are then joined to a plastic filler rod. It is often used in the production of plumbing fittings, and water/chemical tanks, among others.Other techniques of plastic fabrication and welding include freehand welding (a much slower process but used in many applications), speed-tip welding (a quicker welding technique used in tight corners), extrusion welding (for big pieces), contact welding (two pieces are joined by pinching their heated tips), andhot plate welding (for larger pieces or complex welding technique). High frequency welding, injection welding, ultrasonic welding, friction welding, spin welding, laser welding and solvent welding are also used.

Safety Procedures involved in Plastic Processing

Like welding other types of materials, plastic fabrication and welding can be extremely dangerous even if done by professionals. Safety while joining plastics should be prioritized at all times. Follow basic safety guidelines like wearing eye protection and other safety gear. Each type of plastic has its own Material Safety Data Sheet, which includes information on hazardous ingredients, info on first aid during fire or explosion accidents and other guidelines from the manufacturer.Back to Top

Fabrication and Welding

Fabrication and Welding Resources

- Home

- Custom Fabrication and Welding

- Fabrication and Welding Apprenticeships

- Fabrication and Welding Books

- Fabrication and Welding Companies

- Fabrication and Welding Courses

- Fabrication and Welding Engineering

- Fabrication and Welding Jobs

- Fabrication and Welding Schools

- Metal Fabrication and Welding

- Plastic Fabrication and Welding

- Precision Fabrication and Welding

- Stainless Steel Fabrication and Welding

- What is Welding and Fabrication

Sponsored Links